The ion exchange membrane cell plant is equipped with 20

electrolysers of type AZM-T-5.6-F2 consist of three blocks of monopolar filler

press type electrolysers and it corresponds to three single electrolysers. The

basis electrolysis element is anode chamber and a cathode chamber separated by

an ion exchange membrane, Type – Flemion – 893

For electrolysis secondary purified brine is being fed to the anode

chamber, purified H2O to the cathode chamber, and while applying DC

current, movement and reaction of substance in the electrolyser will take

place. In anode chamber electrolysis of NaCl occurs, turning Cl-

into Cl2 on the anode mesh, Na+ ions moves to the cathode chamber

through the ion exchange membrane. Generated Cl2 gas & anolyte

flow up to the anode gas seperator by the driving force due to the gas lift

effects, where chlorine gas is separated and anolyte is recycled through

circulation pipe. While a part of anolyte overflow as depleated brine.

Anode side

reaction

NaCl --> Na+ + Cl-

Cl- --> ½ Cl2

+ e-

In cathode chamber, decomposition of water occurs, produces hydrogen

gas and OH- ion. OH- ions forms NaOH together with the

sodium ions that has passed through the membranes. Generated H2 gas

and NaOH flow up to the cathode gas seperator by gas lift effects, where H2

gas is separated and caustic is recycled through circulation pipe, while a part

of caustic soda overflows as product [32%].

Cathode side

reaction

2H2O + 2e- --> H2 + 2O-

Na++OH- -->NaOH

Water in the anode chamber will move to the cathode chamber through

the membranes by electro osmosis and osmosis. Membrane do not permit the

movement of chloride ions and NaCl diffusion to the cathode chamber, transfer

of hydroxide ions to the anode chamber. Transfer of those ions results in a

loss of current efficiency. Hydroxide ions if any diffused form the cathode

chamber to the anode chamber will produce oxygen gas, hypochlorite and chlorate

by reacting with chlorine gas

2 NaOH + Cl2 --> NaCl +

NaOCl + H2O

6 NaOH + 3 Cl2--> NaCl3

+ 5 NaCl + 3H2O

4 NaOH + 2Cl2 --> O2 + 4 NaCl + 2 H2O

electrolyser :

AZM – T – 5- 6 F2 type electrolyser consist of the following major components

1. Anode

elements

The electrolyser contains 15 anode elements. It consists of one

anode frame and a pair of anode meshes spot welded on both sides of anode

frame.

Anode frame made of Titanium composed of rectangular

pipe to form anode chamber, conductive rods welded with ribs to pass electrical

current from equalizing burbars on to anode meshes.

Anode mesh is titanium made expanded metal coated with

RuO2 catalyst with an area of 1.71 m2 [1.5 m x 1.14m]

2. Cathode

elements

There are 18 cathode elements in one electrolyser, which comprises

three types consisting of twelve C2 – Type elements with a pair of

cathode mesh on both sides of cathode frame, three C-1 type with one cathode

meshlocated on Fixed head side and three C-3 type with one cathode mesh located

on movable head side. Cathode Frame made of stainless steel [Sus – 3ios] is

composed of rectangular pipes to form cathode chamber, equalizing busbar to

conduct electrical current, ribs and coil springs to support cathode meshes.

Cathode mesh is copper made punched metal with nickel plating and Raney nickel

plating and is attached on the cathode frame by using sealing gaskets, bolts,

special jigs 4 nuts: effective area of one cathode element is same as that of

anode element, such as 1.7q x 2m2 = 3.42m2.

3.

Gaskets

EPDM (Ethylene Propylene diene monomel) gaskets with

special structure are placed between flemion membrane & anode / cathode

elements.

4.

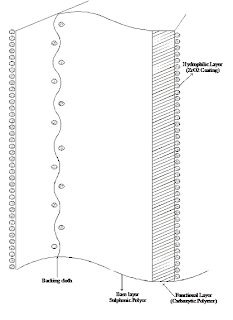

Flemion membrane

The membrane material consist of a copolymer made up of

tetrafluoroethylene and carboxylated / sulphonised perfluoro vinyl ether. There

are thirty sheets of membranes with effective area of 1.71m2

contained in one electrolyser & are installed between anode & cathode

elements.

5. Anode

gas seperator bottom header

Both are made of titanium and equipped with nozzles to

connect anode element by flexible hoses one butterfly valve is installed in b/w

the above for anolyte recycling

6. Cathode gas seperator & bottom header

Both are made of stainless steel and equipped with

nozzles to connect cathode elements by flexible hoses. One butterfly valve is

installed in between the above for caustic recycling

7. Cell frame

Electrolyser supports are made of carbon steel & consists of

base support, movable head, fixed head, sliding rail for frame, He-rods and

insulators. Anode & cathode elements membranes and gaskets are placed

between movable head and fixed head and are fastened together by the press

unit.

8. Insulation frame

This is for insulation of each block of electrolyser and are made of

rubber lines carbon steel.

9. Linking busbar

There are four linking busbars made of copper are is installed in

one electrolyser.

MEMBRANE

CELL PLANTS

Advantages

1)

Pure

sodium hydroxide

2)

Electrical

energy consumption only about 77% of that of ‘Hg’ process

3)

No ‘Hg’

asbestos used

4)

Flexibility

of operation

5)

Less space

requirement as compared to another

Disadvantages

1)

NaOH – 33%

only produced

2)

Cl2

gas contains O2

3)

Very high

purity brine required

4) Present high cost and short life time of

membrane

STRUCTURE OF MEMBRANE

Major

impurities present in membrane process

Calcium and Mg

Ca2+, Mg2+ forms precipitate on the membrane

layer and reduce current efficiency by alloy using hydroxyl ions to penetrate

further in to the membrane from catholyte. There fore in the feed brine the

content of Ca2+ combined with Mg should be kept below 20ppm

Strontium and SiO2

They form hydroxide and silicate on the membrane & decrease

current efficiency by combined effect. Limiting value is 0.02ppm or less when

SiO2 content will be in the level of 5ppm and Sr 0.06ppm or less

when SiO2 content is lower than 5ppm.

Aluminium

Al decreases the current efficiency allowable range is <0 .1ppm=".1ppm" span="span">

Ba & I

Ba and I forms

ppt and reduce current efficiency by combined effect

Allowable values are

Ba < 1.0 ppm when I2 is < 0.1ppm

Ba < 0.5 ppm when I2 is < 0.2 ppm

Iron

Iron form ferric oxide allows pH and can ppt at the anode phase ‘O’

the membrane and reduce current efficiency. Max allowable value in the feed

brine is 1ppm or less.

Nickel

‘Ni’ is in the feed brine affects membrane voltage performance and

to be kept below 0.01 ppm or less. It rarely comes from the brine and the

principle source is from the cathode due to the attach of hypochlorite and

diffuces through the membrane during electrolyser shutdown.

Pb and Hg

Membrane will allow heavy metals in the brine and effects. Cathode

coatings and voltage performance of the electrolyser. Its limiting values 0.2

ppm and 10ppm respectively.

Protection

of electrolysers from electric corrosion by leak current

The circuit of electrolyser is protected from grounding

for preventing current leakage to the ground and therefore avoiding electric

corrosion. Current leakage occurer during fluid flow in or out from the

electrolysers. For preventing corrosion of electrolysers and pipings, following

methods are adopted.

1.

Leak current via the feed brine

When leak current flows out via the piping of feed brine, galvanic

corrosion develops on anode gas separator and anolyte recycle pipe. An anticorrosive electrode is

provided. Inside the pipe in the feed brine inlet of each electrolysers. This

anticorrosive electrode is electrically connected with the intercell busbar

between the electrolyser on the anode side for keeping the potential of

anticorrosive electrode nearly identical with that of the anode potential that

is higher than the electrolyser potential. In this way, leak current will flow

out only from the anticorrosive electrode to the feed brine side without affecting

electrolyser.

2.

Leak

current through the depleated brine is prevented by providing an anticorrosive

electrode inside the depleated brine line of each electrolysers, electrode is

electrically connected with the anode side busbar.

3.

Leak

current through the catholyte is eliminated by installation of a current

breaker on the catholyte outline of each electrolyser

4.

To prevent

the leak current – inside the electrolyser sacrifice electrodes are installed

at the inlet and outlet nozzle of first and third block

5.

In case an

accidental grounding is sustained in a piping system, galvanic corrosion will

take place in the piping system & equipments. To avoid such electrolytic

corrosion & anticorrosive electrode is provided in common main piping of

feed brine and depleated brine line.

6.

For the

purpose of protecting the wiring from an excessive current in the case that the

anticorrosive electrode and the connected wires short circuit to the ground the

line leading to the anticorrosive electrode is provided with a trigger fuse

[5A]. A alarm is displayed on a panel in the control room in the case of blow

out of the trigger fuse for periodical checking the leak current, connect a DC

ammeter to a plug in type terminal of the trigger fuse.

Operation

The secondary purified brine is fed to the brine head tank by the

secondary brine pump through a heat exchanger or cooling or heating purpose.

Purified brine is admitted to the electrolysers through a pressure control

valve PICA – 3201. Then it flows in branches to the anode chambers of each

electrolyser through a rotameter. Demineralized water from the head tank is

admitted to the electrolysers through a pressure control valve PICA – 3202 and

flows to the cathode chamber of each electrolysers. Through rotameters. During

normal operation both control valve are to be put in ‘auto’ operation.

During electrolysis, at anode chamber, decomposition of

30% of NaCl in feed brine taxes place, forming depleated brine at the anode

side, which overflows from the anode gas seperator and enters the depleated

brine receiver. Chlorine gas enters at the anode gas seperator is separated

from the anolyte & is collected into the chlorine gas main piping and sent

to the treatment section, at cathode chamber, caustic soda is produced

overflows from the cathode gas seperator & flows through the current

breaker to the receiving tank [32% lye tank]. Caustic soda lye produced is

pumped to the main storage tank through a cooler in which it is cooled by

cooling tower water. The level in the caustic soda receiving tank is maintained

by pumping through a level control valve, LIC – 3102 which can be put ‘auto’

operation. The H2 gas generated in the cathode chamber enters the

cathode gas seperator when the gas is separated from the catholyte and is

collected in the H2 gas main piping and to the H2 gas

treatment section. The pressure of hydrogen gas in the main piping is that of H2

holder pressure.

Monopolar

and Bipolar systems

In the electrolysers for NaOH production membrane are

clamped vertically b/w mesh like cathode and anode. The cells are filled with

electrolytes and gas separating means are provided outside. Many cells unit can

be stocked by a like fitter press to constitute one electrolyser with ample

production capacity

Industrial electrolysers for NaCl electrolysis using

membrane cell process and classified into different cell arrangement.

1.

Monopolar system

In the monopolar system cells are electrolyser are

electrically connected in parallel and the electrolysers are connected in

series.

Mono polar cells consisting of the following elements.

1.

Dimensionally

stable titanium anode plate held in a frame with +ve busbar method

2.

The cation

exchange membrane

3.

A cathode

plate in a frame with negative busbar attached

A number of cells are assembled together to form one monopolar

electrolyser. Since individual cells in a monopolar electrolyser are connected

in the voltage across the electrolyser is same as the voltage across individual

cell. For conversion of Hg cell to membrane are cell monopolar system is

preferred as the existing installation can be used.

Bipolar system

These are constructed in modules. A module consist of

rectangular box like construction where are face is anode and other is cathode.

In the middle there is a partition place which divides the modules into anode

and cathode compartments.

These modules are joined together with the membrane in

b/w them. The anode chamber of one of module, the membrane and the cathode

chamber of the next module constitute one cell. Several such modules are

assembled together to form one bipolar electrolyser. Since the individual cells

in bipolar electrolyser are connected in series, voltage across one

electrolyser is the sum of individual voltage. In bipolar system electrolysers

are connected in parallel.

1 comments :

Post a Comment